Experience

Shurhold.Ind

Factory Intern

Shurhold.Ind

Factory Intern

May. 2025 - Aug. 2025

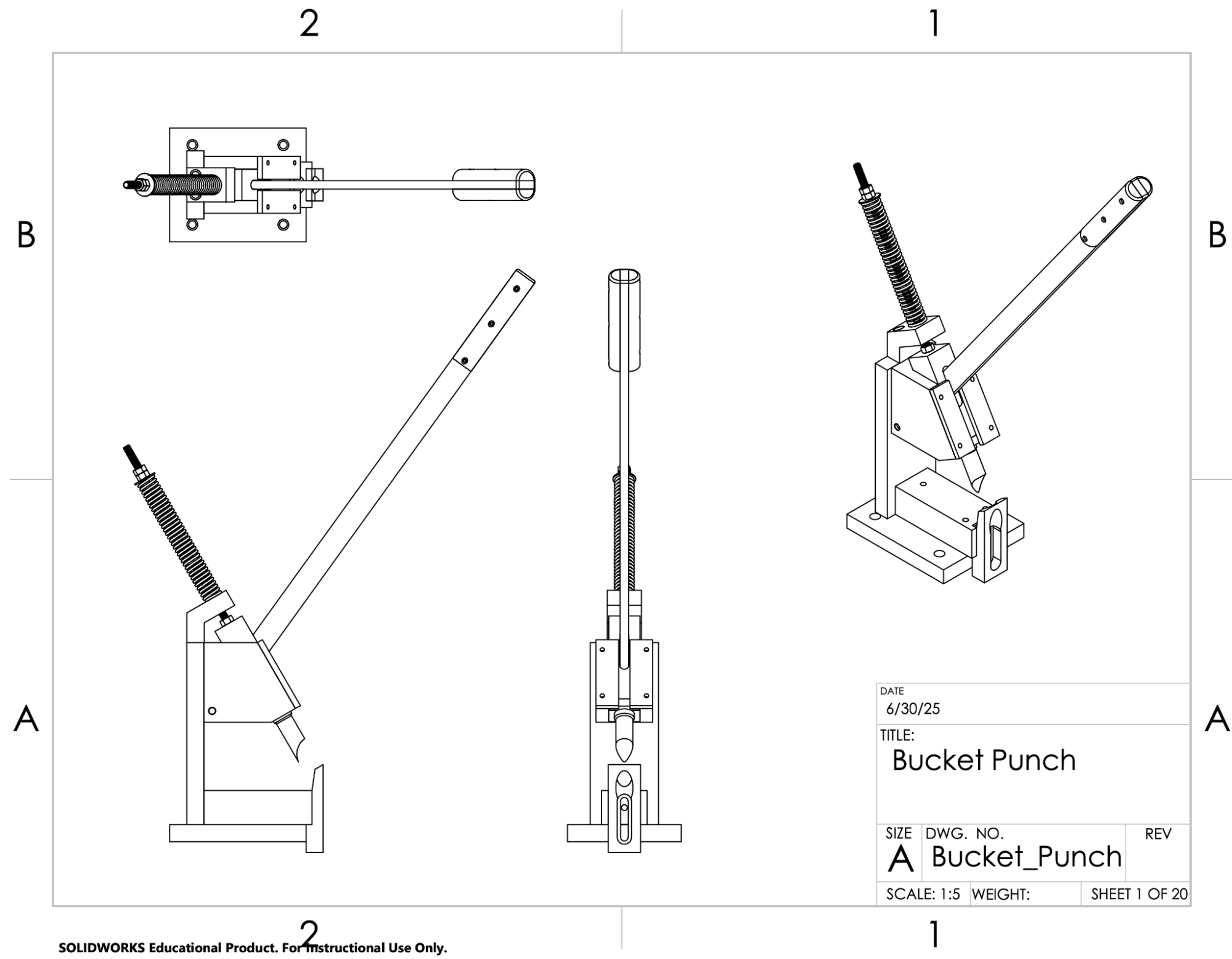

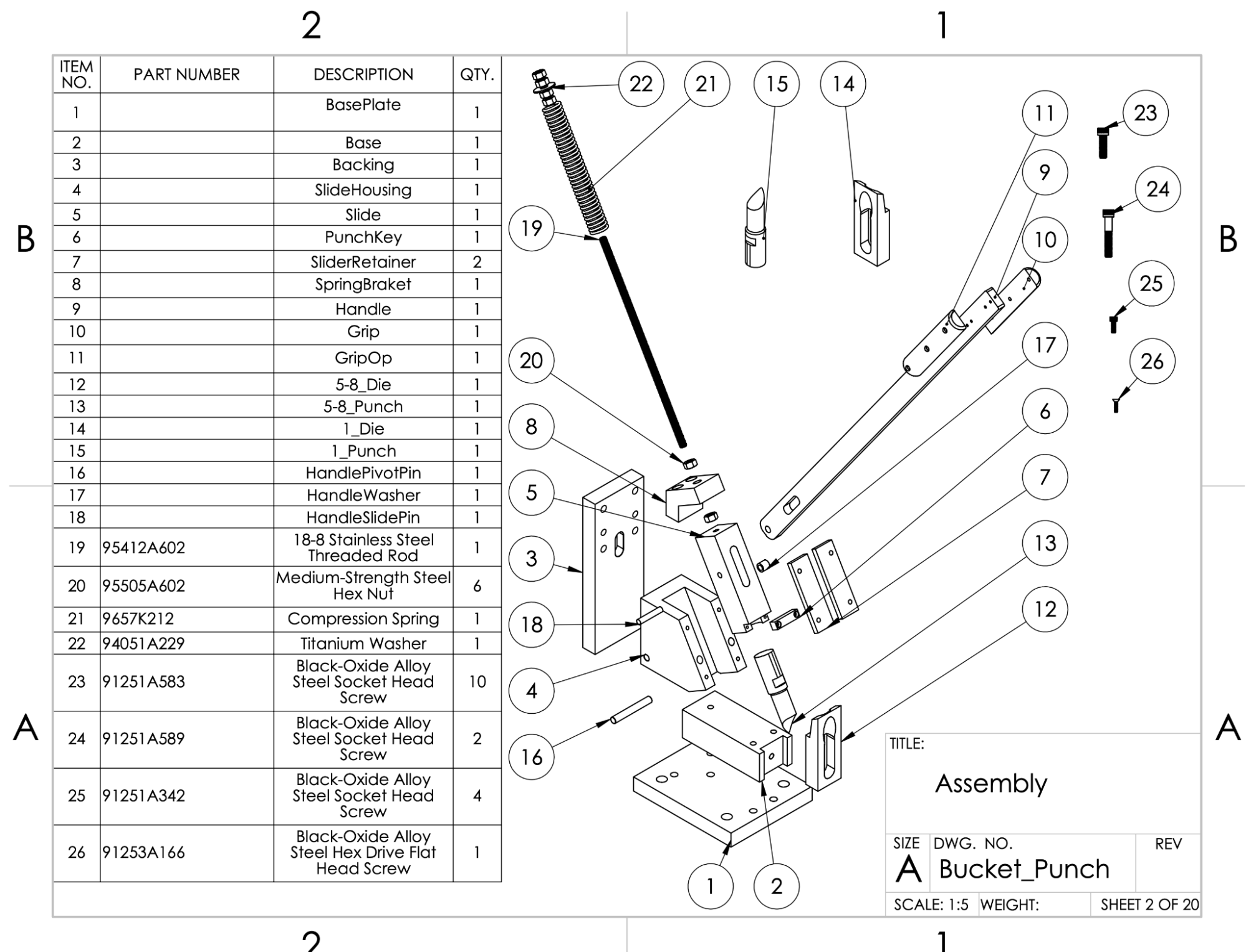

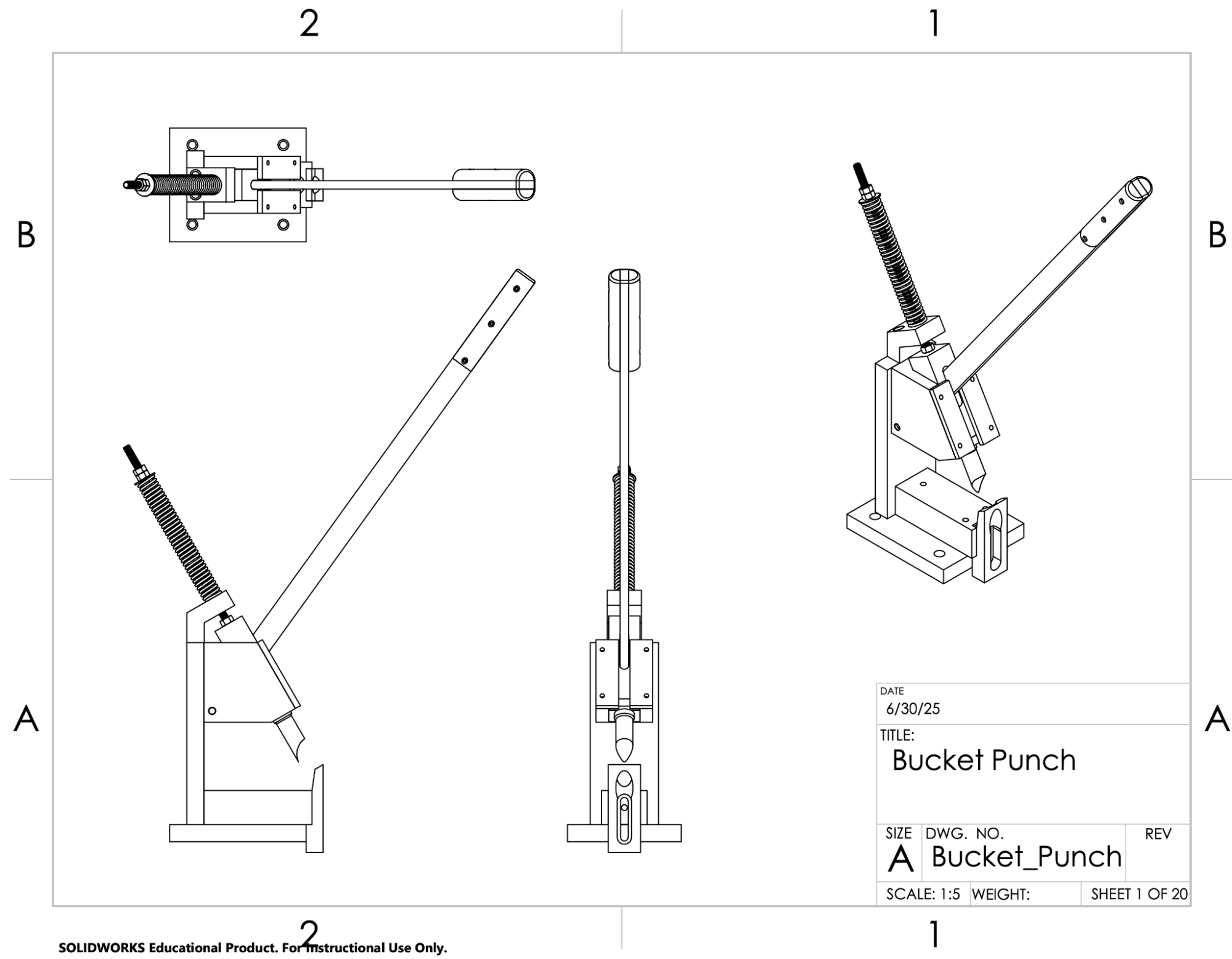

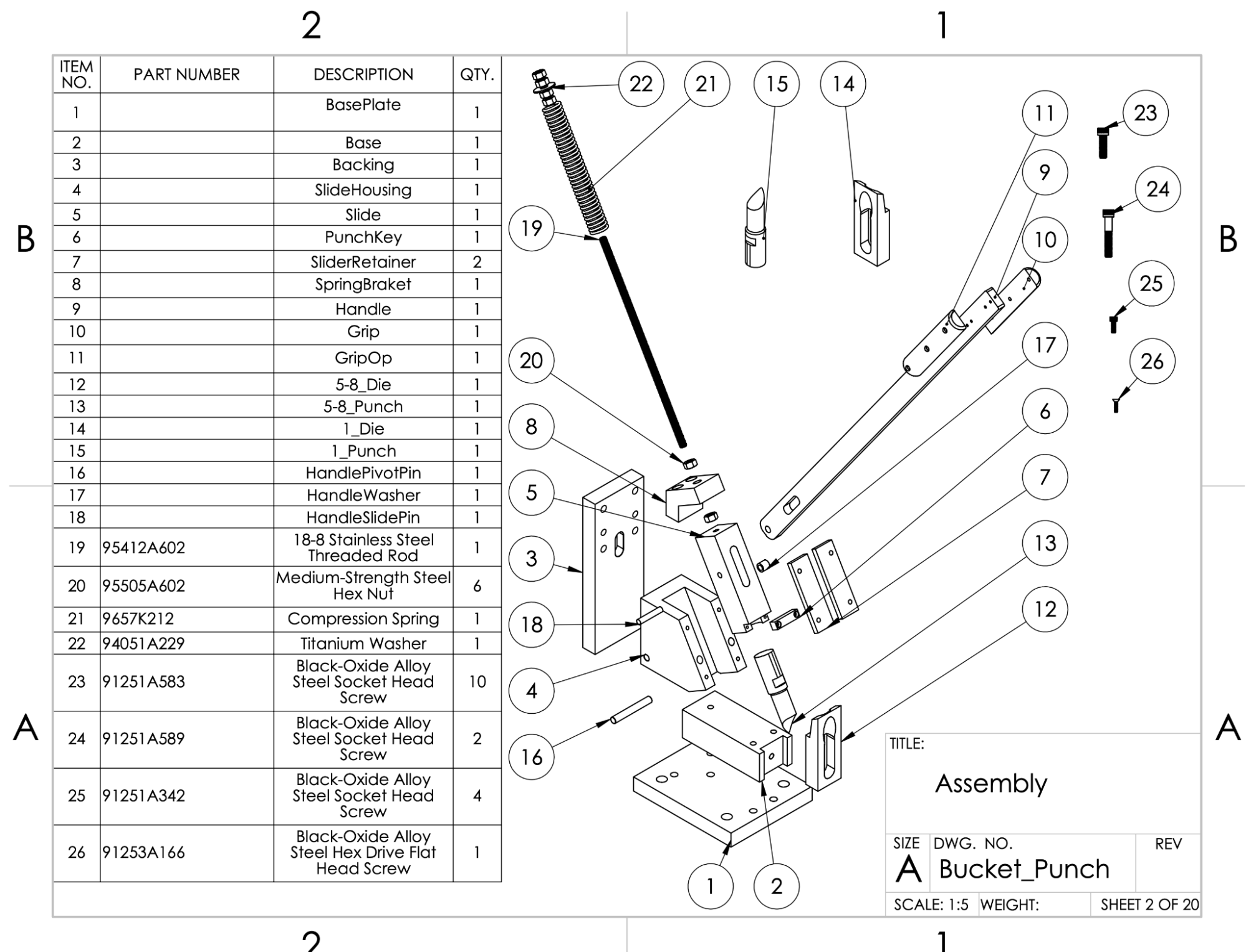

Bucket Hole Punch

Reverse-engineered the Shurhold bucket punch machine. Drafted up-to-date documentation, parts list, CAD models, and engineering drawings. These are now available to replace broken components as needed.

Bucket Hole Punch

Reverse-engineered the Shurhold bucket punch machine. Drafted up-to-date documentation, parts list, CAD models, and engineering drawings. These are now available to replace broken components as needed.

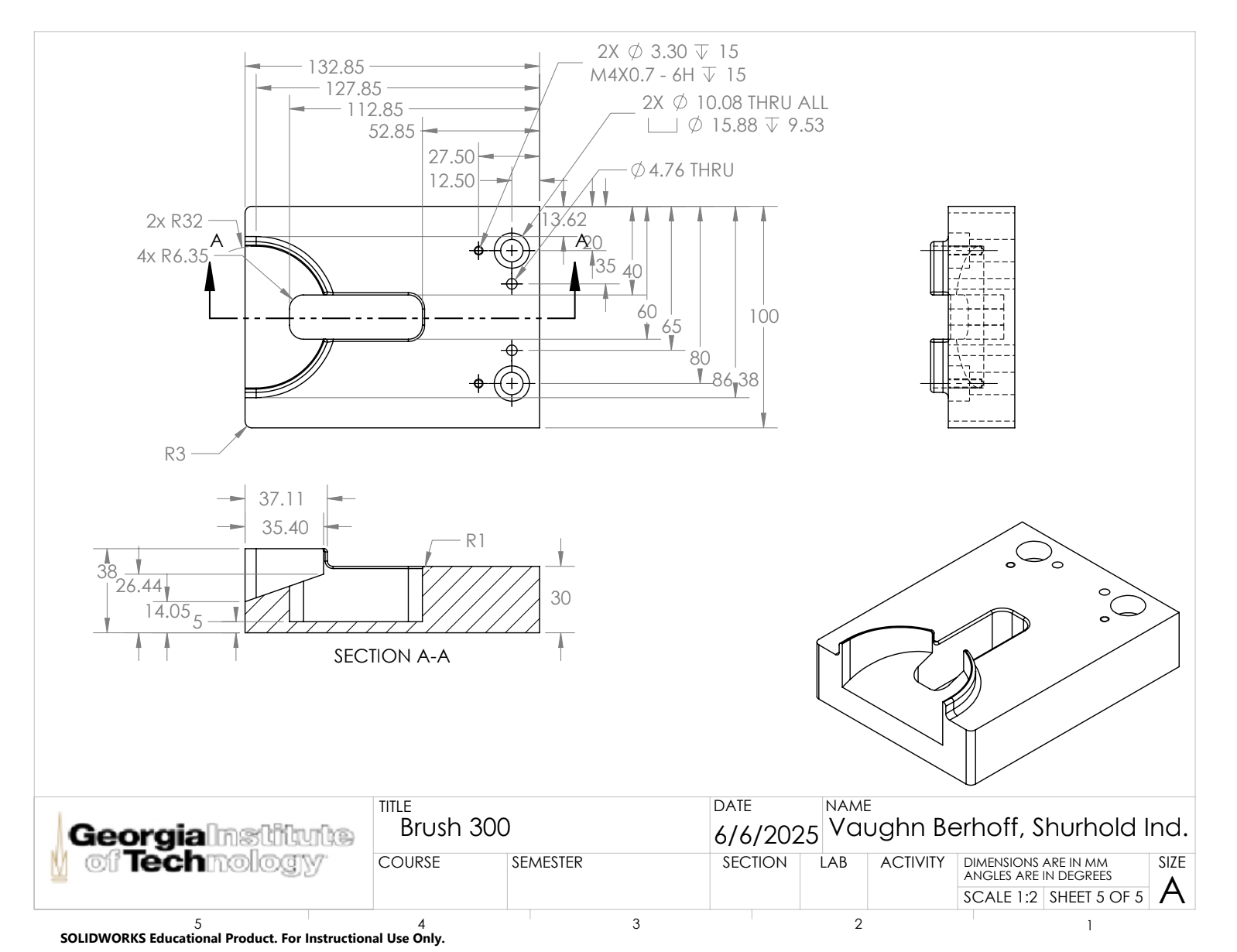

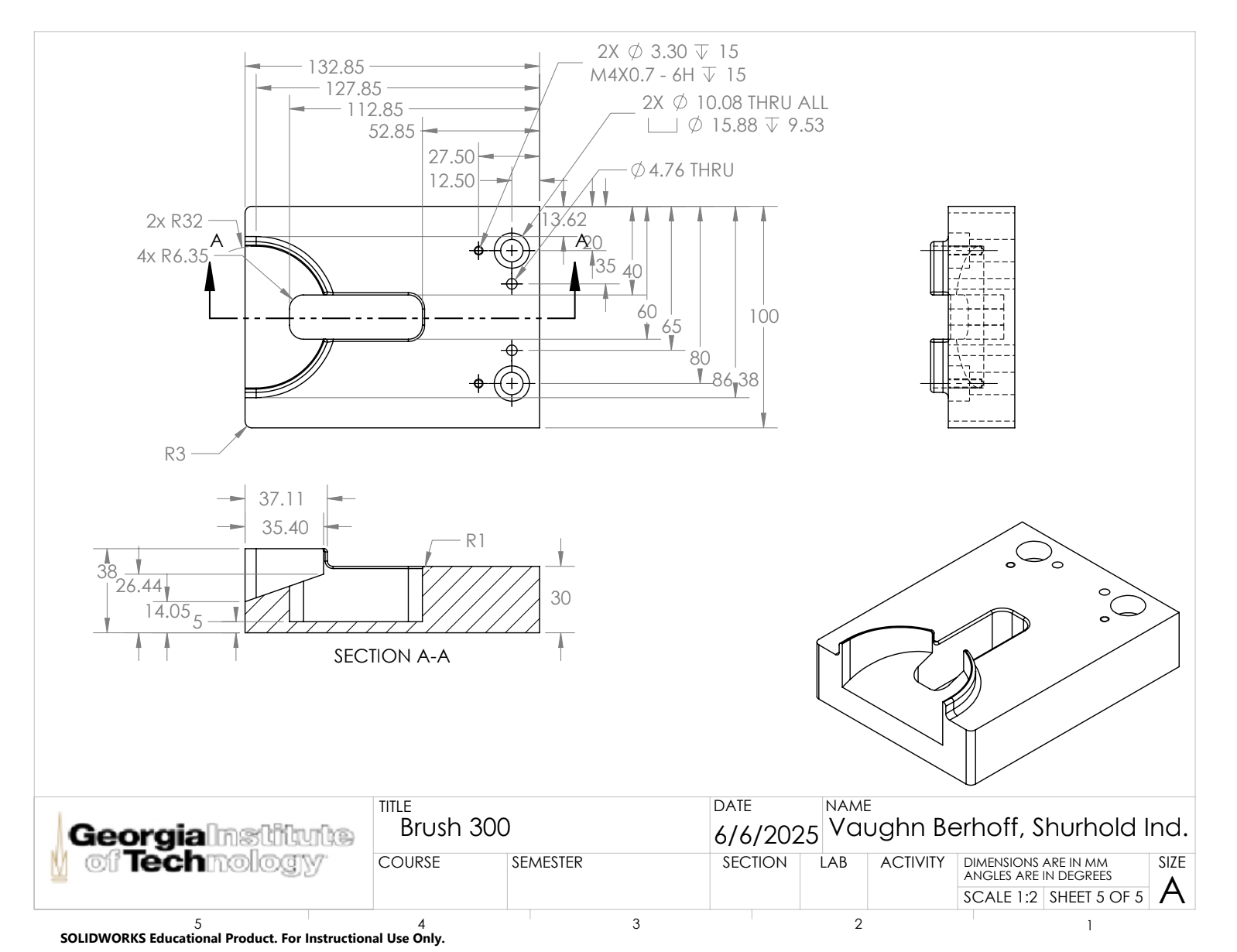

Brush Bumper Installation

Nicknamed "Steve" by the factory crew, this dual-piston bumper installer streamlined the assembly of rubber bumpers onto multiple brush models. Designed to stretch and snap the band on fresh brushes. Replaced an outdated system and decreased assembly time by 25%.

Brush Bumper Installation

Nicknamed "Steve" by the factory crew, this dual-piston bumper installer streamlined the assembly of rubber bumpers onto multiple brush models. Designed to stretch and snap the band on fresh brushes. Replaced an outdated system and decreased assembly time by 25%.

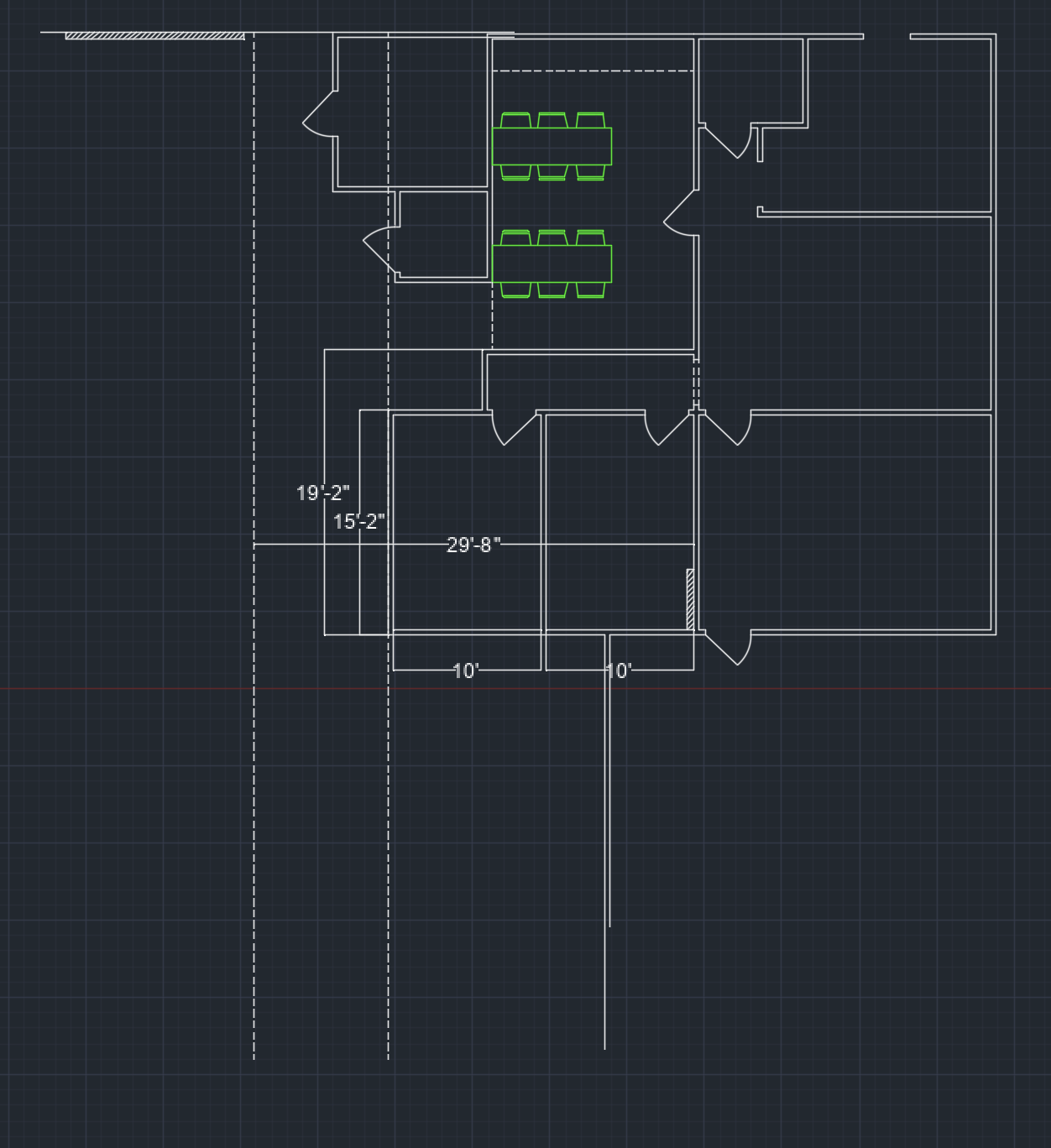

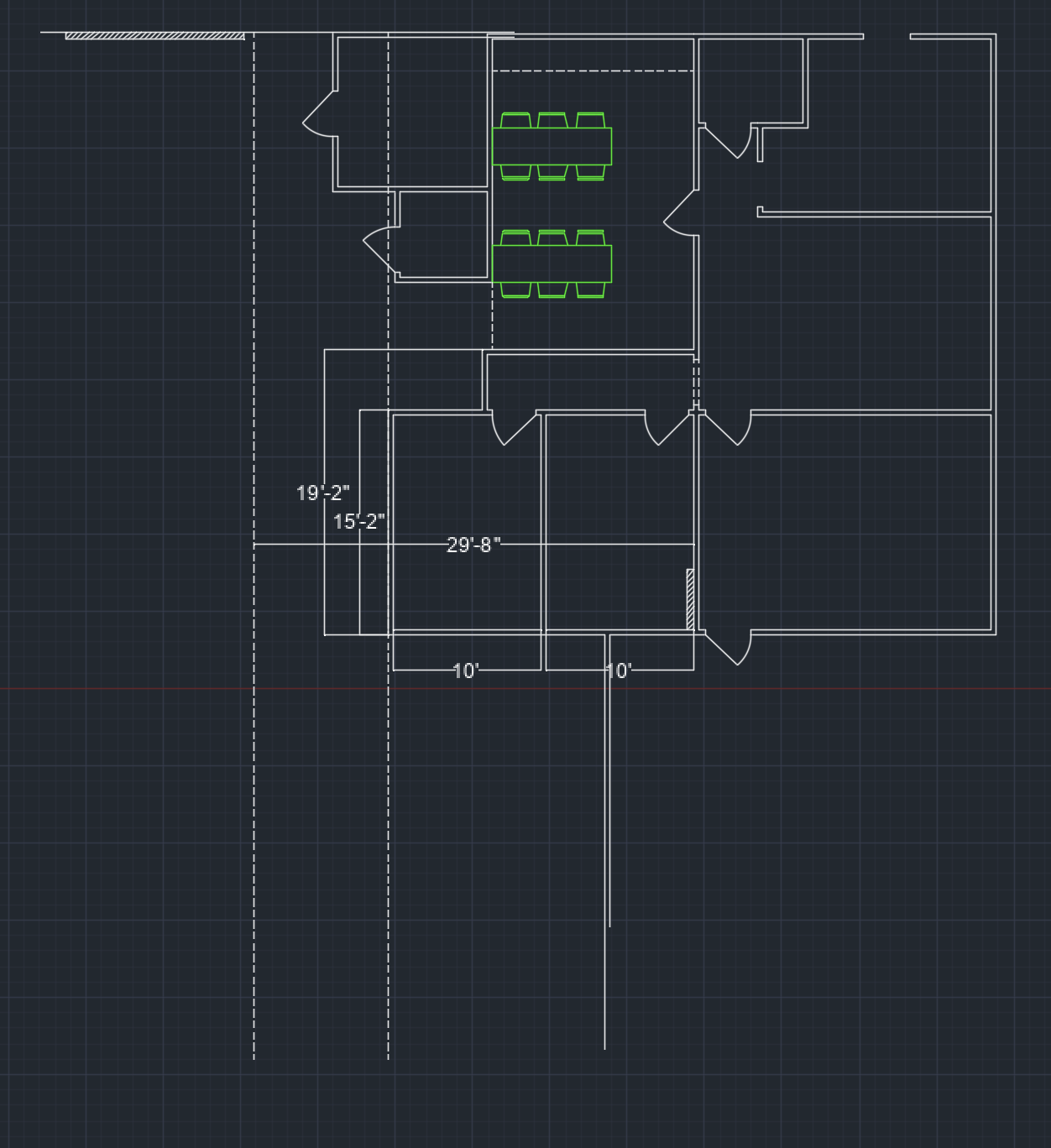

Office Layout

Worked alongside architects and construction workers to draft a layout, primarily utilizing AutoCAD, for the addition of two new offices. Optimized for ease of access and staff communication.

Office Layout

Worked alongside architects and construction workers to draft a layout, primarily utilizing AutoCAD, for the addition of two new offices. Optimized for ease of access and staff communication.

Lineage Biomedical

Position Held*

Lineage Biomedical

Position Held*

May. 2024 - July. 2024

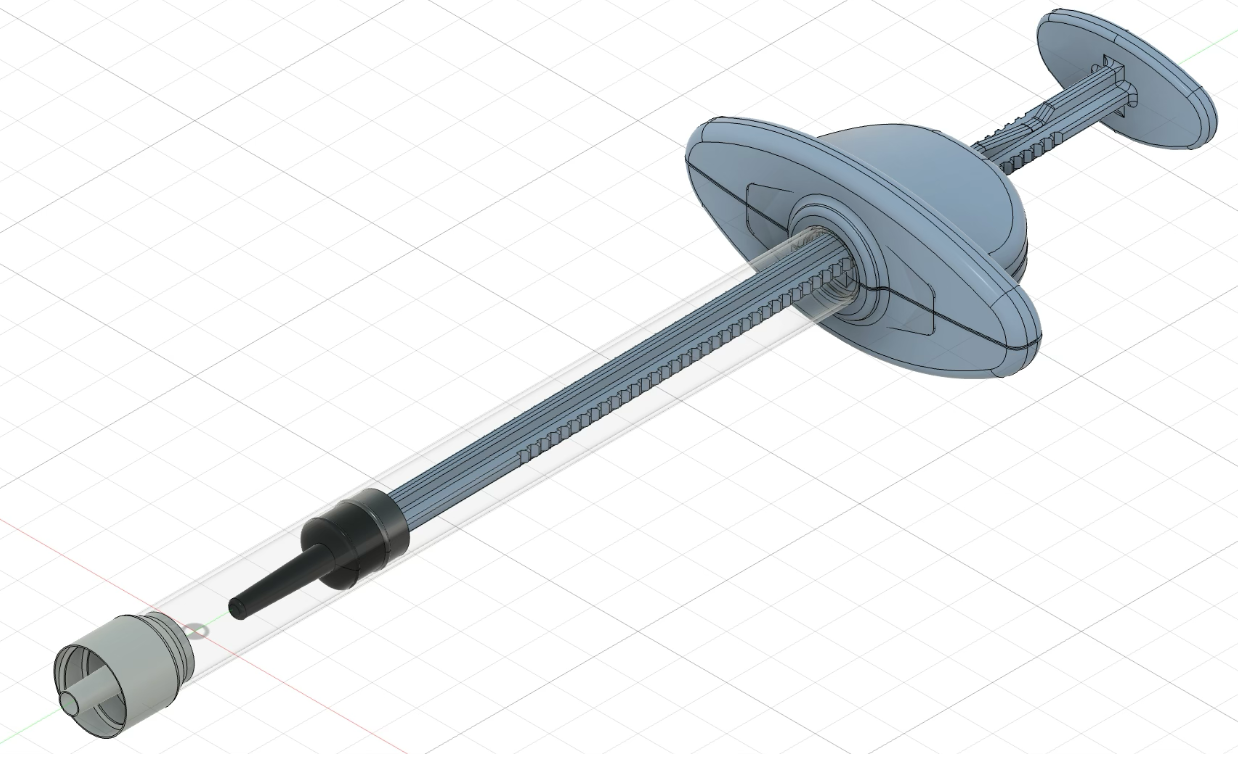

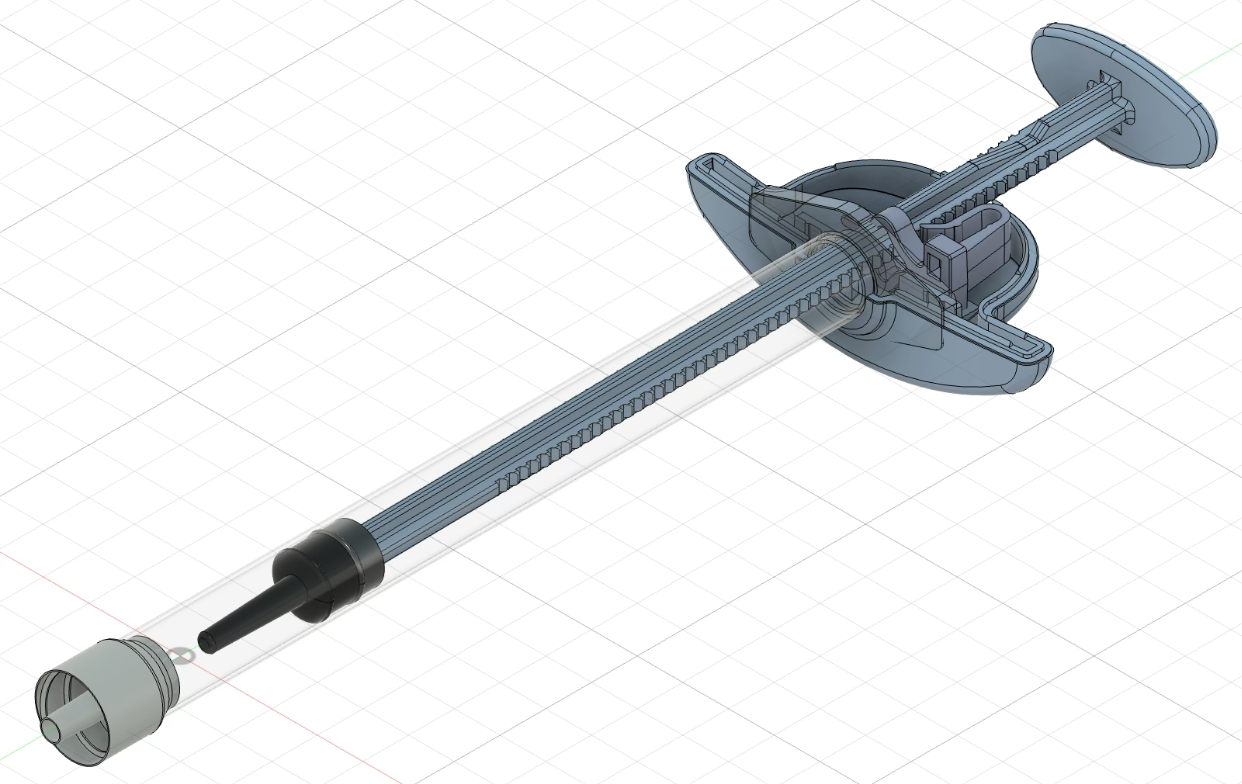

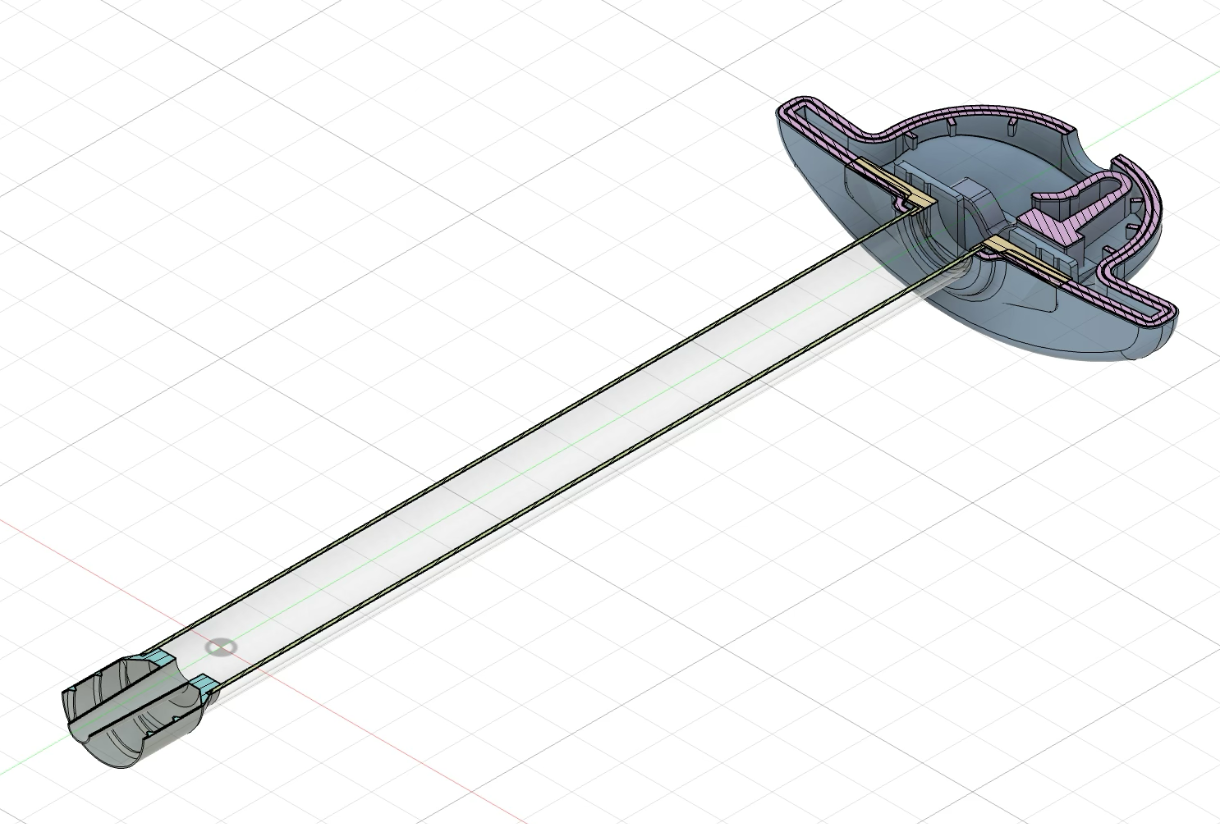

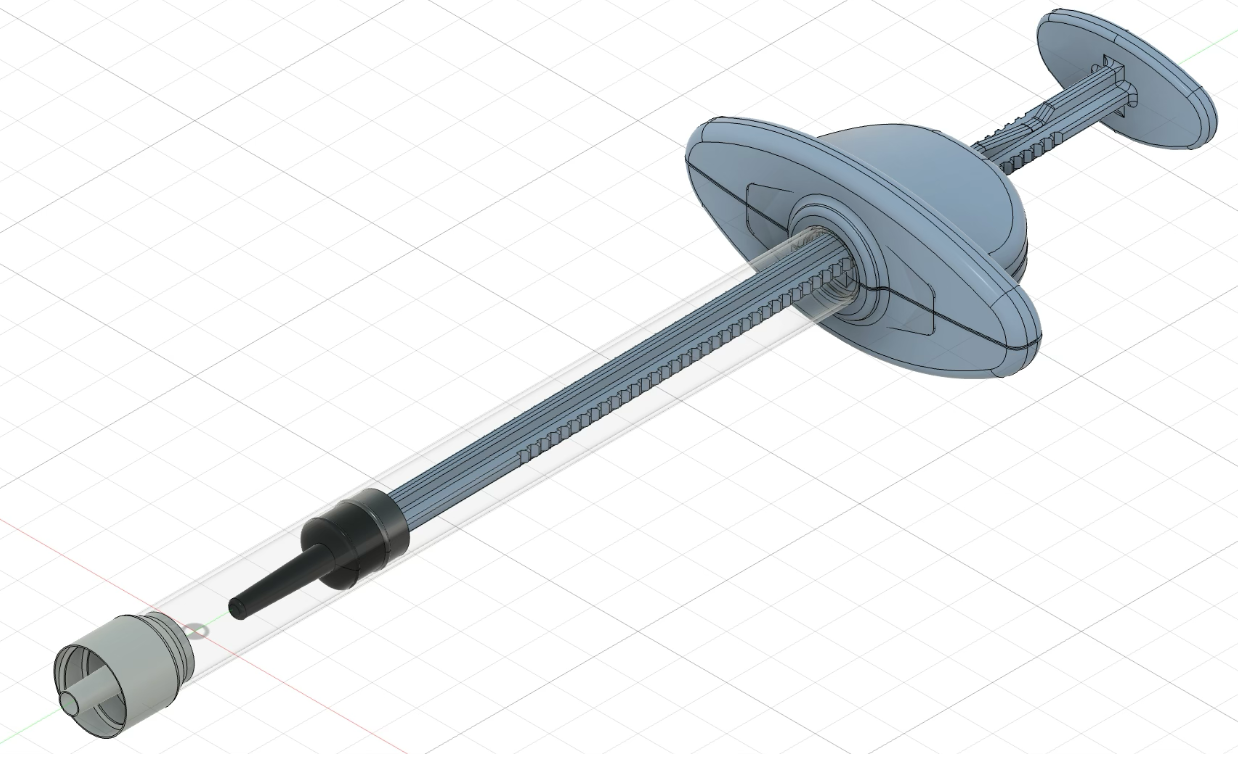

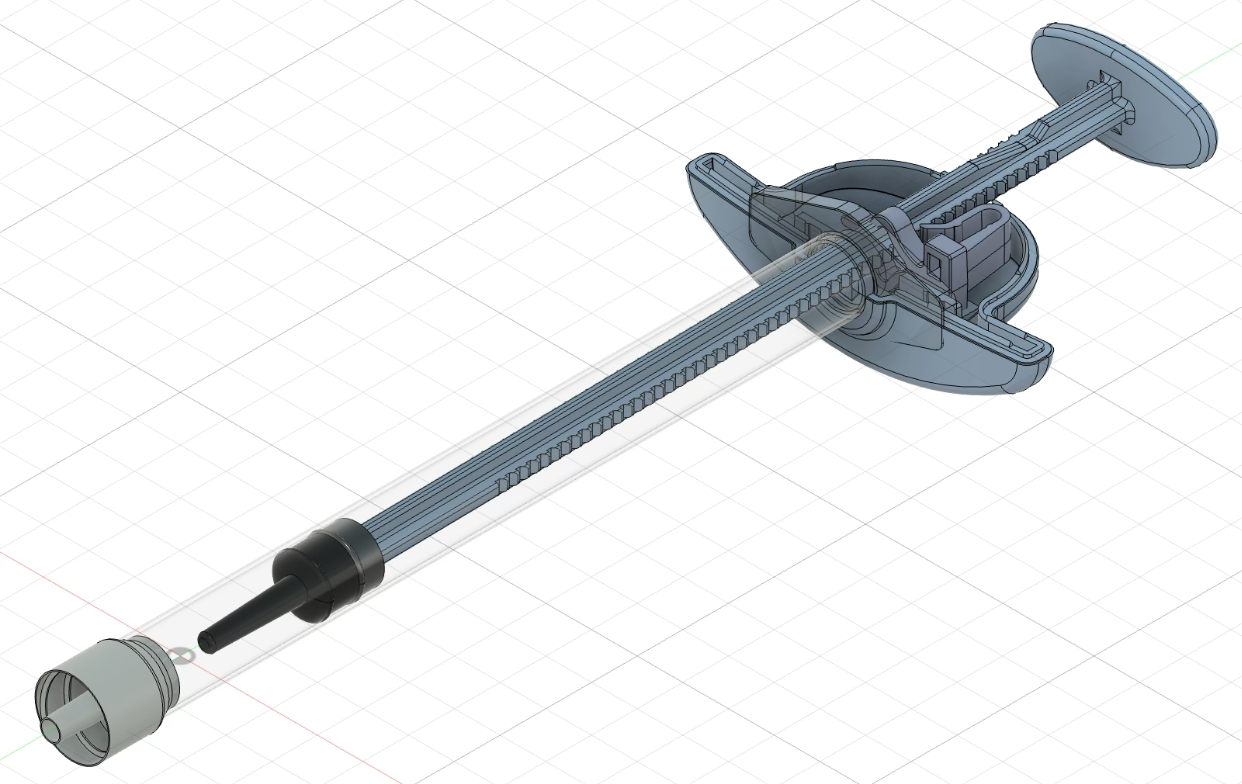

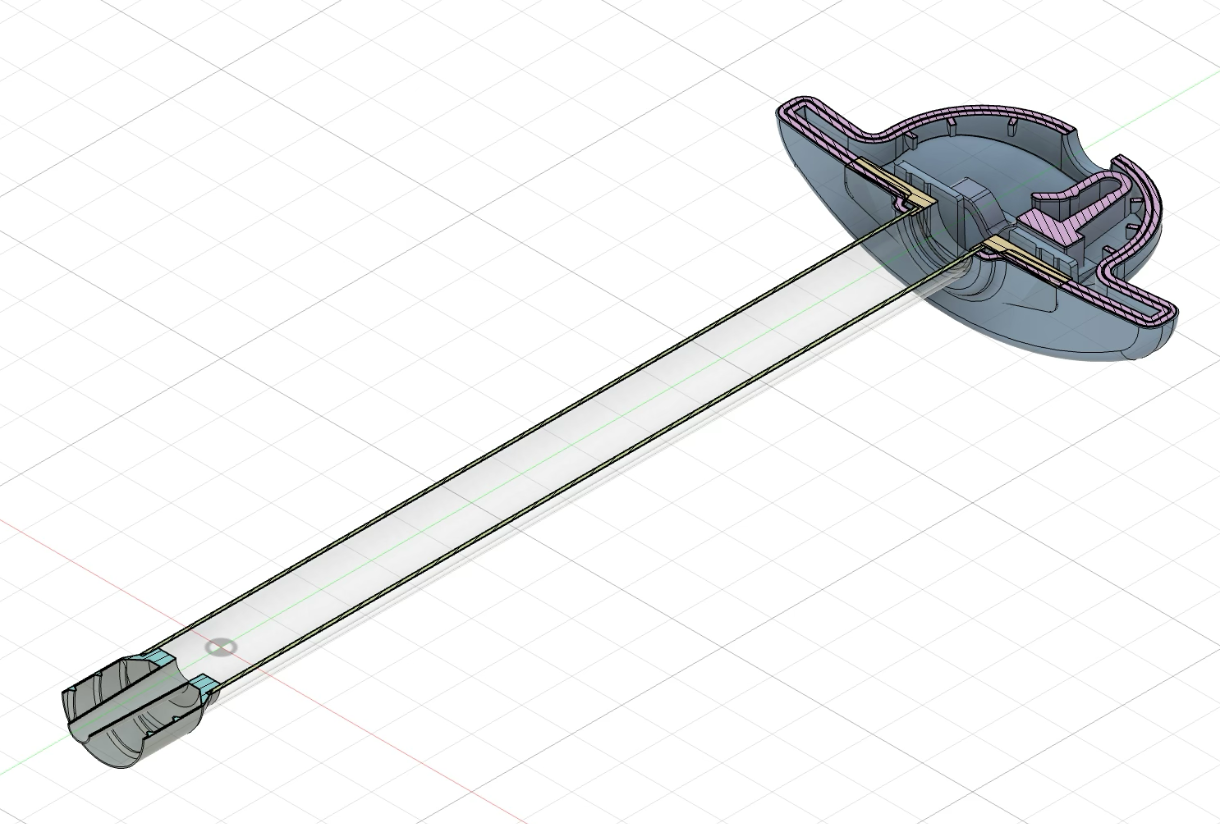

Nava-Click

Process: Observed a product to redesign in CAD Fusion 360. Critical decisions to maximize functionality & realism while minimizing manufacturing difficulty. Communicate with the company for an optimal outcome.

Working for Lineage Biomedical, I redesigned their existing product in CAD to produce a 10x scaled model to show at trade shows. During the design process, I considered several factors, including transportation, manufacturing costs, and durability. I also contributed my experience in 3D printing to aid in manufacturing.

Materials: 3D-printed PLA, TPU, & other Wood. The right three pictures demonstrate different viewing layers of the sarringe mechanism.

Nava-Click

Process: Observed a product to redesign in CAD Fusion 360. Critical decisions to maximize functionality & realism while minimizing manufacturing difficulty. Communicate with the company for an optimal outcome.

Working for Lineage Biomedical, I redesigned their existing product in CAD to produce a 10x scaled model to show at trade shows. During the design process, I considered several factors, including transportation, manufacturing costs, and durability. I also contributed my experience in 3D printing to aid in manufacturing.

Materials: 3D-printed PLA, TPU, & other Wood. The right three pictures demonstrate different viewing layers of the sarringe mechanism.

Bikes Plus

Bike Mechanic

Bikes Plus

Bike Mechanic

November. 2020 - October. 2023

Bike Mechanic

Working at Bikes Plus I gained skills as a mechanic learning the ins and outs of bike functionality. One of my favorite projects was frame swapping a Canyon Neuron CF8. Process: disassembled and stripped all components off the old frame including suspension, derailer, brakes, handlebars, and wheels. Cleaned and fixed old parts assembling them back onto the new frame. Truing the new bike to the customer's attributes.

Bike Mechanic

Working at Bikes Plus I gained skills as a mechanic learning the ins and outs of bike functionality. One of my favorite projects was frame swapping a Canyon Neuron CF8. Process: disassembled and stripped all components off the old frame including suspension, derailer, brakes, handlebars, and wheels. Cleaned and fixed old parts assembling them back onto the new frame. Truing the new bike to the customer's attributes.